Laser Welding and Laser Marking of plastics

LASER WELDING

LASER MARKING

Laser marking is an innovative procedure for precisely labelling a wide variety of materials such as wood, paper or leather. In order to mark plastics with lasers, one needs as a general rule, depending on the use case, to develop the correct plastic compound for the end product, which will be subjected to the laser marking procedure in the course of constant development tests. Treffert here offers both the know-how for developing laser-markable plastics and the option of making extensive tests on the plastics at six different lasers in our own innovation centre. This makes it possible to considerably reduce the development time for laser markable plastics depending on the use case. If you are interested, just submit a query online or contact our application engineers and let them consult with you about the topic of laser marking at your business location.

Laser Welding for Plastics –

The Modern Joining Procedure for Many Areas of Application

Questions and answers about Laser Welding

Why Laser Welding?

Every new technology must have strong arguments to replace established methods. Why use lasers for plastic welding? There are four significant arguments:

- Laser welded joints resist high mechanical loads, they are gas tight and often achieve the same strength as the base material.

- With lasers, almost any kind of seam weld contour can be realized and there is a solution for nearly every workpiece geometry.

- Minimal thermal and mechanical stress input is applied: What you weld is what you see. The welding is so precisely localized, that even

sensitive components very close to the weld remain unaffected. - The results are surfaces with perfect quality, no micro particles, glue or roughness.

Four factors for success

As with any other process, laser welding of plastics needs specific conditions to be a success.

There are the following key factors:

- Choice of suitable polymers, additives and pigments.

- Use of the right laser source with suitable optics.

- Appropriate joint configuration and small gap width.

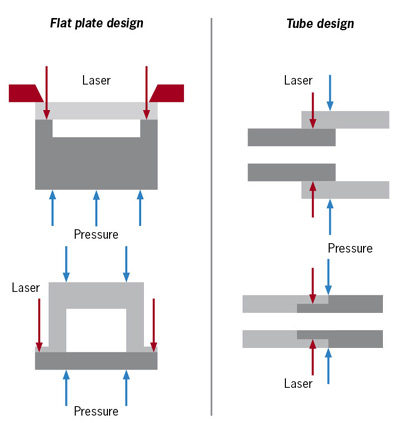

- Optimized clamping technology, allowing free access of the laser beam to the seam and applying sufficient pressure on the components.

What can be welded?

PE, PP, PS, ABS, SAN, PA6, PA6.6, PC, PMMA, PSU, PEEK, PET, PBT…

There is also a rule of thumb for natural materials: What you can weld ultra-sonically can also be laser welded… and many more.

Laserwelding of polymers is already successfully used in numerous applications: in the automotive, electronic and telecommunication industries, medical device technology, human care and household devices.

Process overview

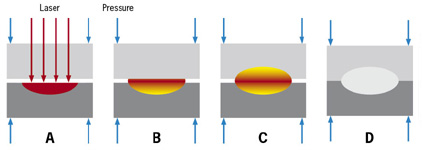

Low heat conductivity and viscosity of polymers means that the most practical welding geometry is overlap welding. Here, the laser beam penetrates the upper material and is absorbed by the lower material. The heating of the latter leads to plastification which bridges the work-piece gap and melts the upper material by heat transfer. Therefore, having a small work piece gap is an important success factor.

Laser light penetrates the upper layer and is absorbed by the lower material (A). The melting of the latter transfers (B) the heat to the upperlayer (C). The mutual melting pool solidifies under external pressure to a high-quality weld (D).

Which laser source?

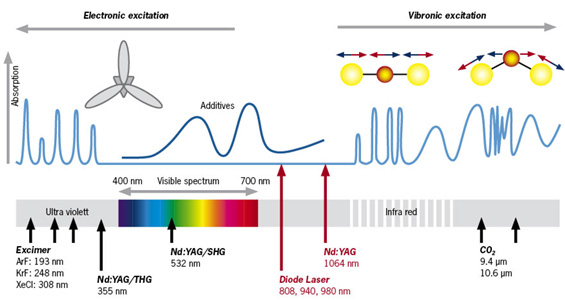

The wavelength is the decisive feature in determing which laser is the ideal one for polymer welding: diode lasers, Nd:YAG or fibre laser. Apart from the difference in wavelengths and the absorption behaviour of certain pigments, the following rules apply:

Nd:YAG lasers are particularly suitable for welding seam widths below 1 mm and for plane welding geometries with scanner head applications.

The new fibre laser demonstrates high reliability and long lifetimes along with high-energy efficiency in comparison to the YAG laser. Further advantages are

their compact size and there are also no consumable costs.

Diode lasers, however, are preferred for wider welding seams, circular seams and simple spot-welds.

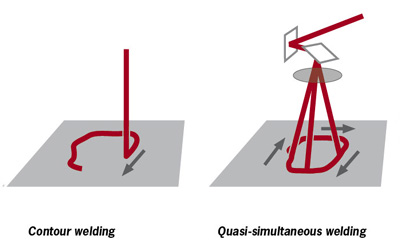

Contour & quasi-simultaneous welding

These two processes show presently the best market presence. With contour welding, the laser beam follows the welding seam, similar to metal welding. Almost any work piece size can be welded. The limits for this technique are set by the tolerable gaps. With quasi-simultaneous welding, the laser beam passes over the entire welding contour several times very rapidly. Beam deflection is done using galvo scanning heads and therefore higher beam quality is essential. The entire welding path melts quasi-simultaneously due to heat buffering and allows the layers to move against each other easily. The pressure on both layers and a suitably designed sacrificial region can bridge larger gaps. On the one hand, quasi-simultaneous welding requires higher laser power; on the other hand, it allows even distortion-free energy input.

Transparency and absorption

All commonly used polymers are more or less trans-parent in undoped condition in the infrared wavelength range of the laser sources (except CO2 lasers). Filler materials, like pigments, provide for the absorption of laser energy. Many colour pigments absorb within the infrared range and can be used for laserwelding. Even simpler, and therefore most common, is the use of carbon black particles acting as absorbers, typically in a concentration of 0.05 – 0.5 %. However, this results in darker colours. There are already standard solutions for black-black and transparent-black welding availabe.

For clear and bright colours, colorants, which are flexible in use, are also available. They absorb only within a certain wavelength range and have no significant influence on the colour. The slight colour changes due to the additives can be adjusted by colour matching.

Most polymers (lighter blue curve) are usually transparent or translucent in the visible and near IR range. By adding pigments (darker blue curve), suitable absorption of the laser wavelength is achieved.

Even colored and also transparent

Welding of light-colored or transparent polymers, which is particularly required in the medical device industry, is successfully achieved with CO2 laser in the case of welding thin films or more general by using the above mentioned laser absorbing high performance additives.

Those have to exhibit high absorption efficiency at the appropriate wavelength and low color impression in the visible range as well as various additional

characteristics: the know-how of an innovative worldwide operating masterbatcher ensures optimum results. Titanium dioxide presents particular problems in relation to beam scattering and low transparency and requires customised solutions for white-white welding.

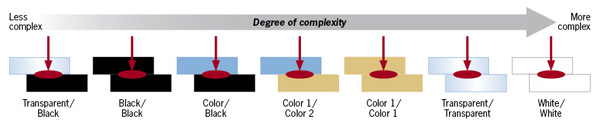

Increasing degree of complexity in overlap welding of polymers. For many applications an experienced partnership between additive producer and masterbatcher is of great advantage.

Easy to compensate residual color with high NIR absorption efficiencies

Another highlight of this innovative product family is the weak, easy to compensate residual color in the visible, in combination with very high absorption effi-ciencies in the Near Infrared (NIR). All members of the Lumogen® IR product line are non-ionic, free of halogen and heavy metals, and toxicologically harmless: excellent preconditions for their use in the medical device industry and other sensitive applications.